Working with the main world building firms in the sector.

We design and build the following systems:

• Compactors control systems

• Shears control systems

• Single and dual shaft grinders control systems

• Coil Press Binder

• Extractor Centrifuge

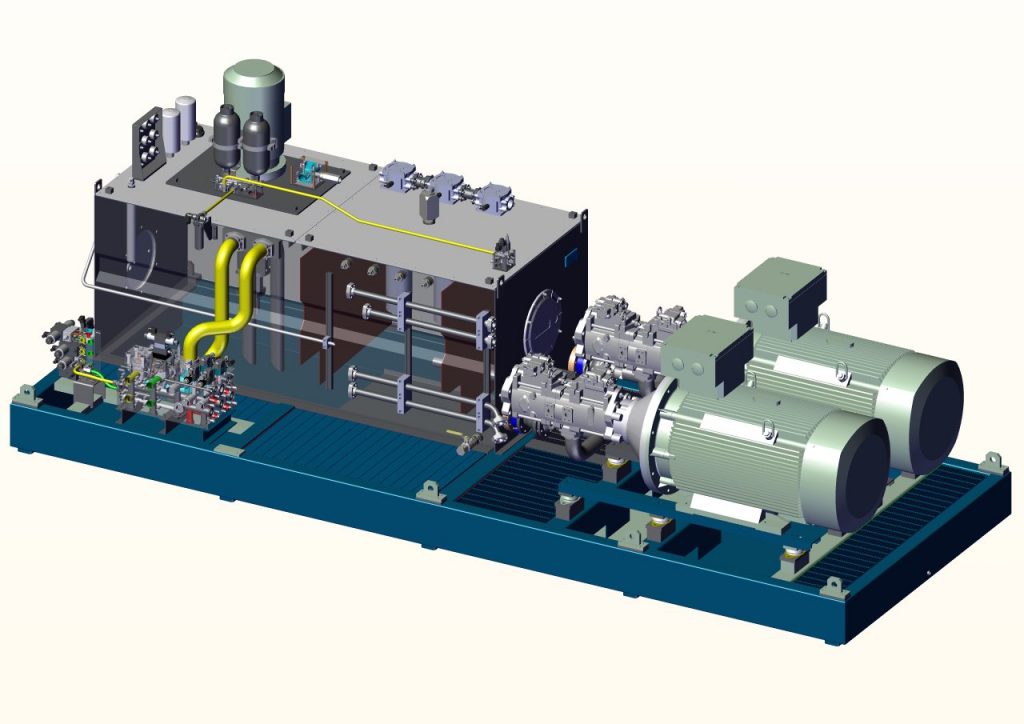

Through the use of a dedicated software, we can also dimension the whole fluid power plant, according to the requested machine cycle.

Expertise:

Power: up to 640 kW [860 hp]

Flow rate: up to 6.000 l/min [1590 gpm]

Pressure: up to 420 bar [6000 psi]

Temperature: -40 °C +60 °C [-40 °F +140 °F]

Certifications: according to: SIL, PED requirements

Process Control: WPS, PQR, NDT, mechanical stress and wearing tests

Engineering international standards: UNI EN ISO 13849, ASME, EU Directives rules and specifi cations IEC61508, IEC61511

Painting: based on customer specifications

Surface treatments: galvanization, phosphating, electrolytic protections, nitrocarburizing, stainless steel surface finishing

Materials: steel, cast iron, ergal

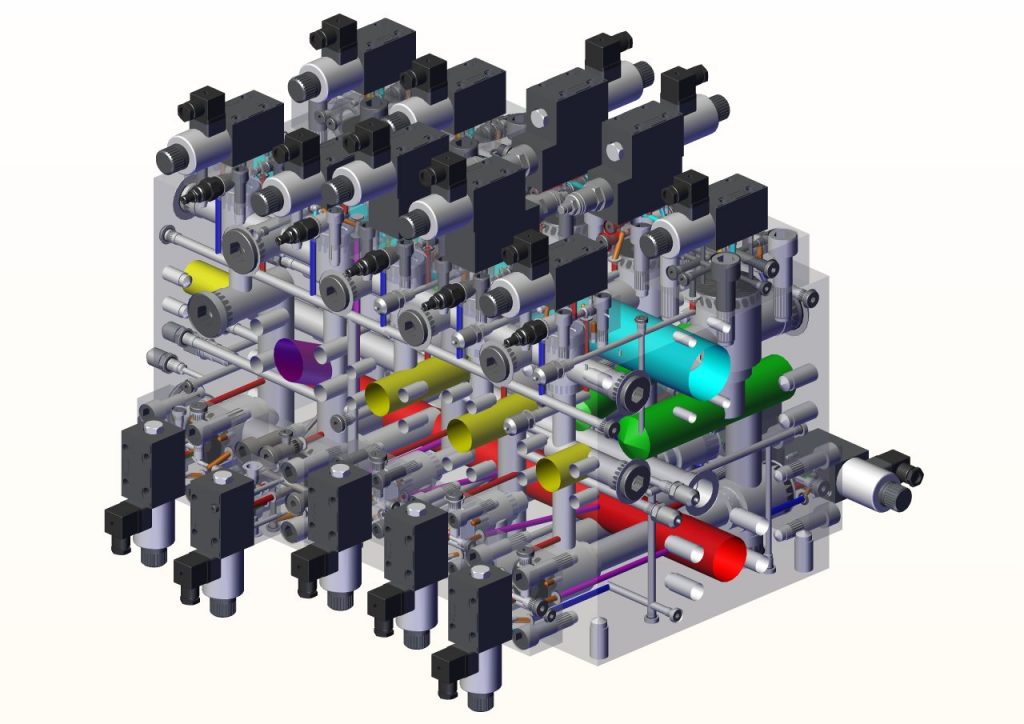

- High-Low Pressure switches

- High Flow Cartridge Valves

- High Performance Air/Oil Heat Exchangers

- Manifold with up to 1m long drilled holes

- High Capacity Accumulators

- Manifold, HPU (Hydraulic Power Unit) and Integrated System full engineering

- Fluid dynamics simulation

- Structural calculation

- Deep analysis and check of every single system parameter with specific and official report release

- Final operational test of the whole system

- World Wide commissioning with high level expertise technicians

- Rigid and flexible piping and on-site full assistance

- 40 years-experience in the hydraulic field and a very passionate team of engineers and technicians who work every day close to our customers