WHAT DO WE DO?

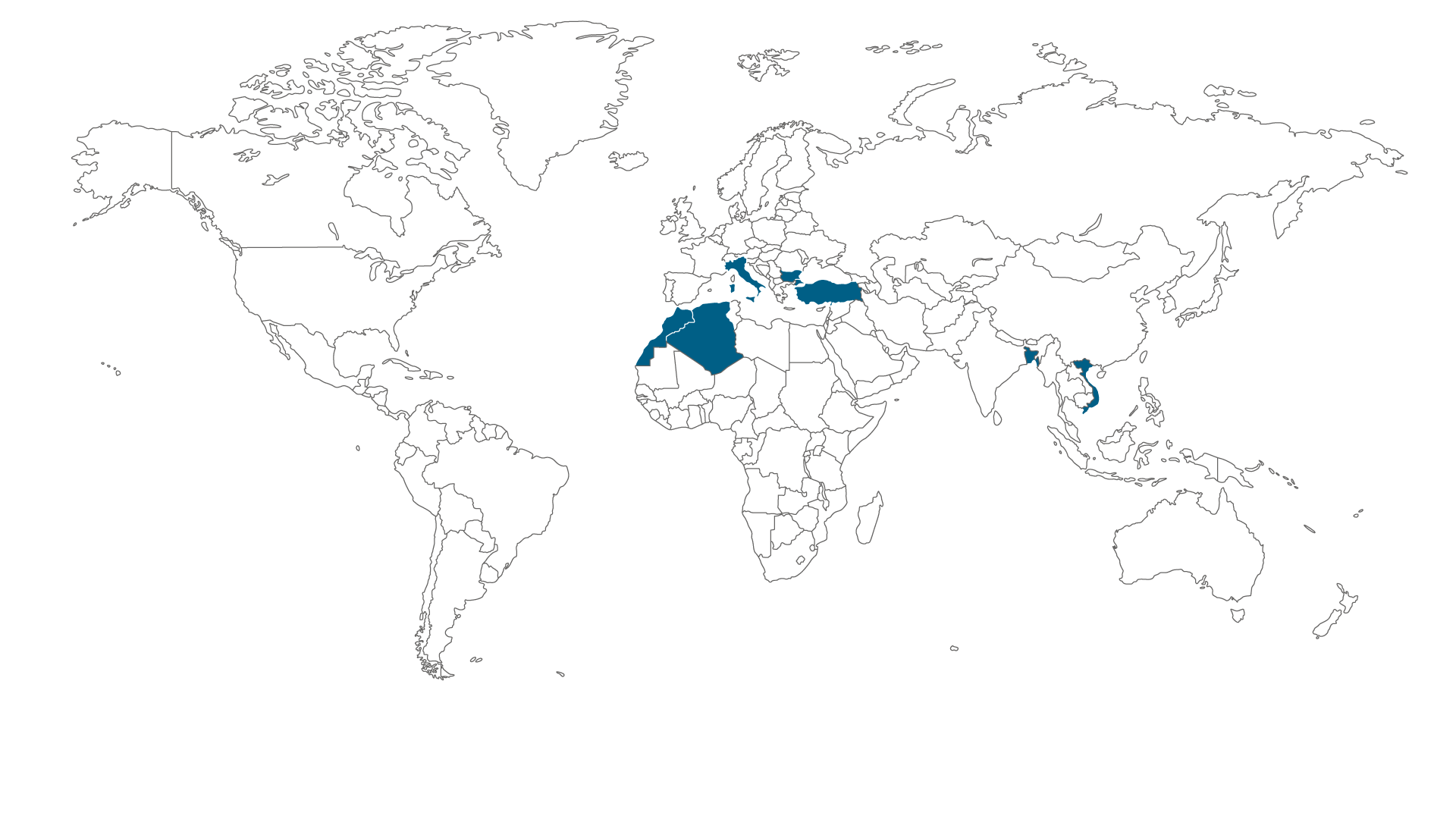

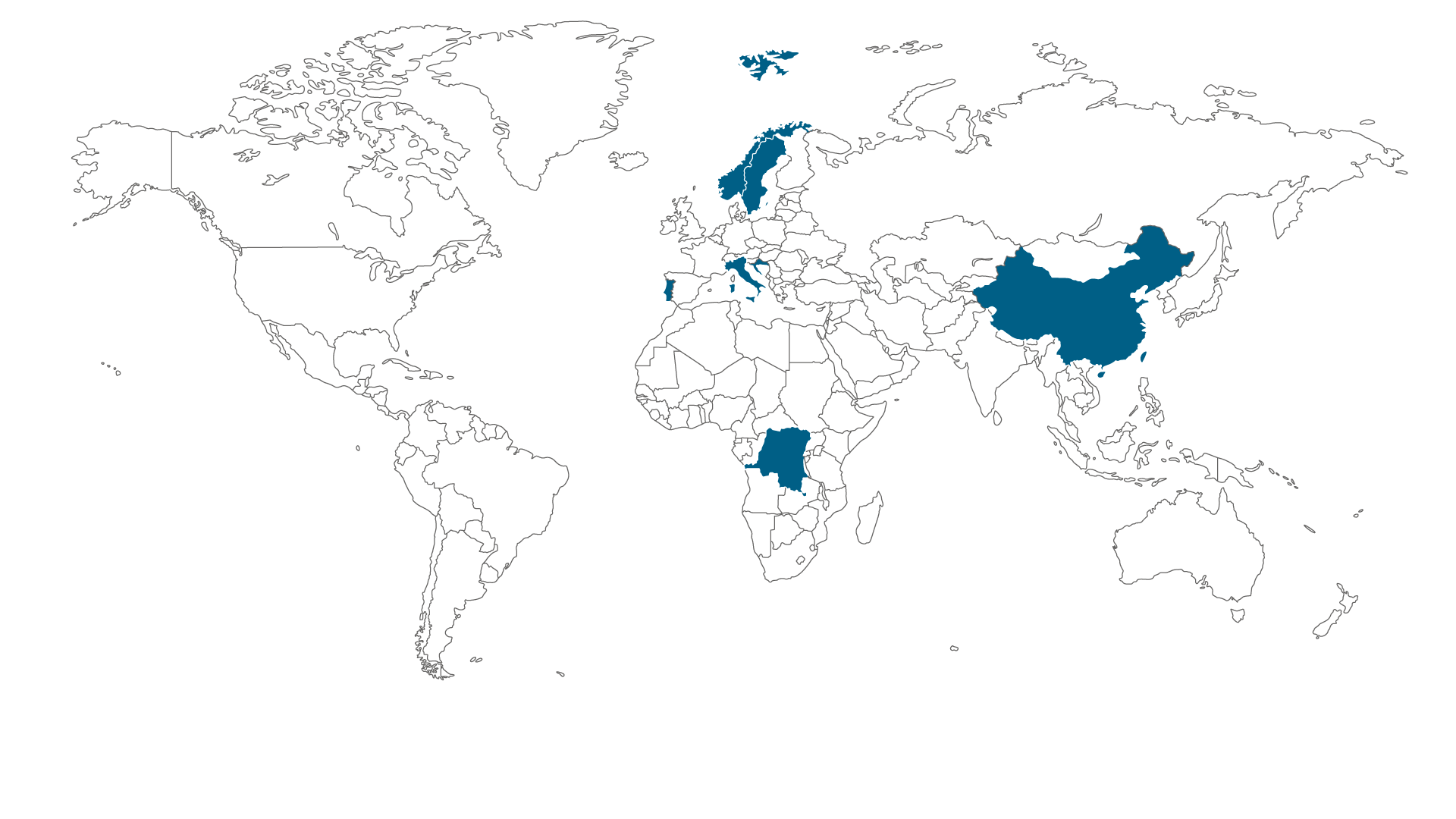

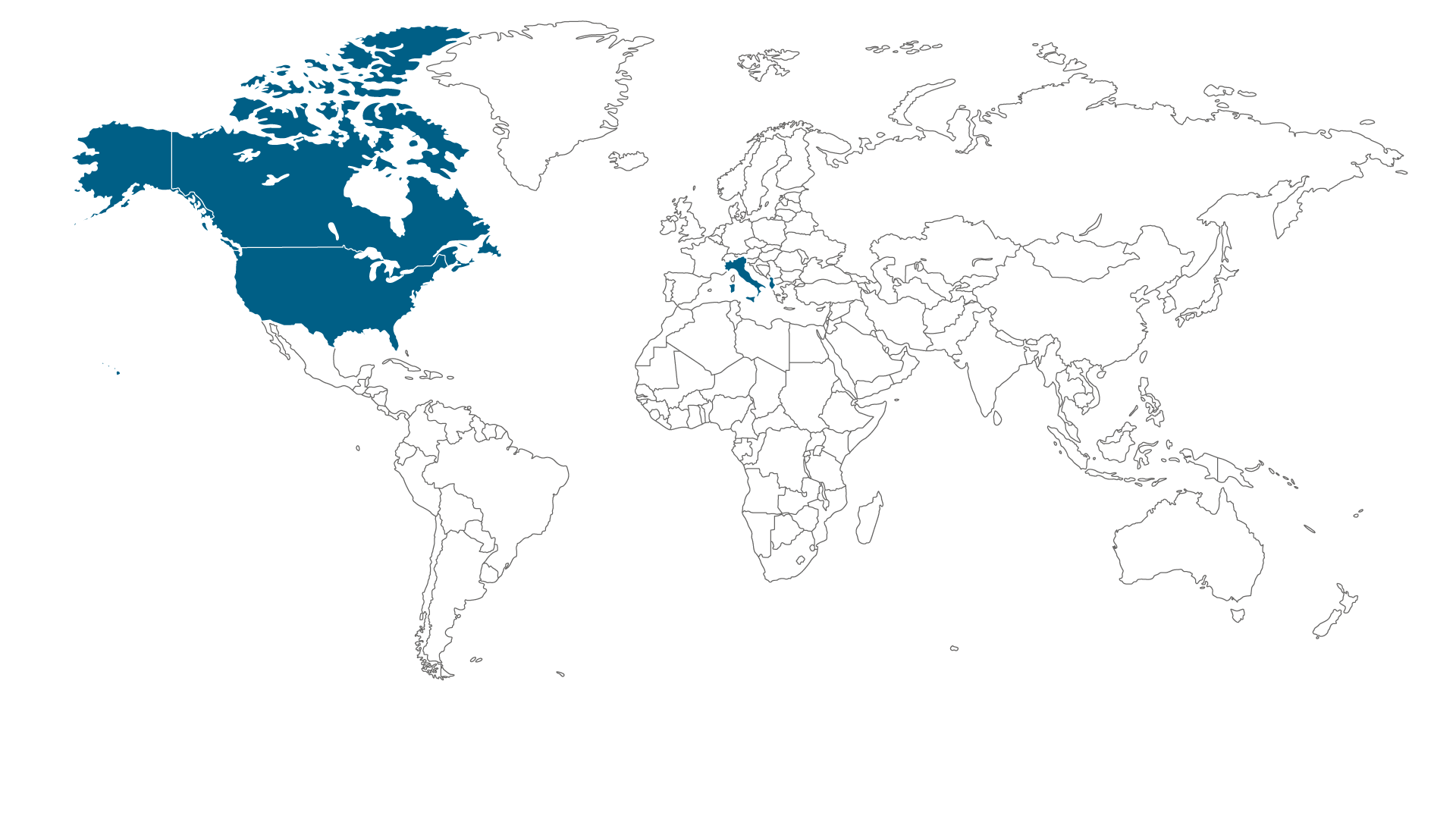

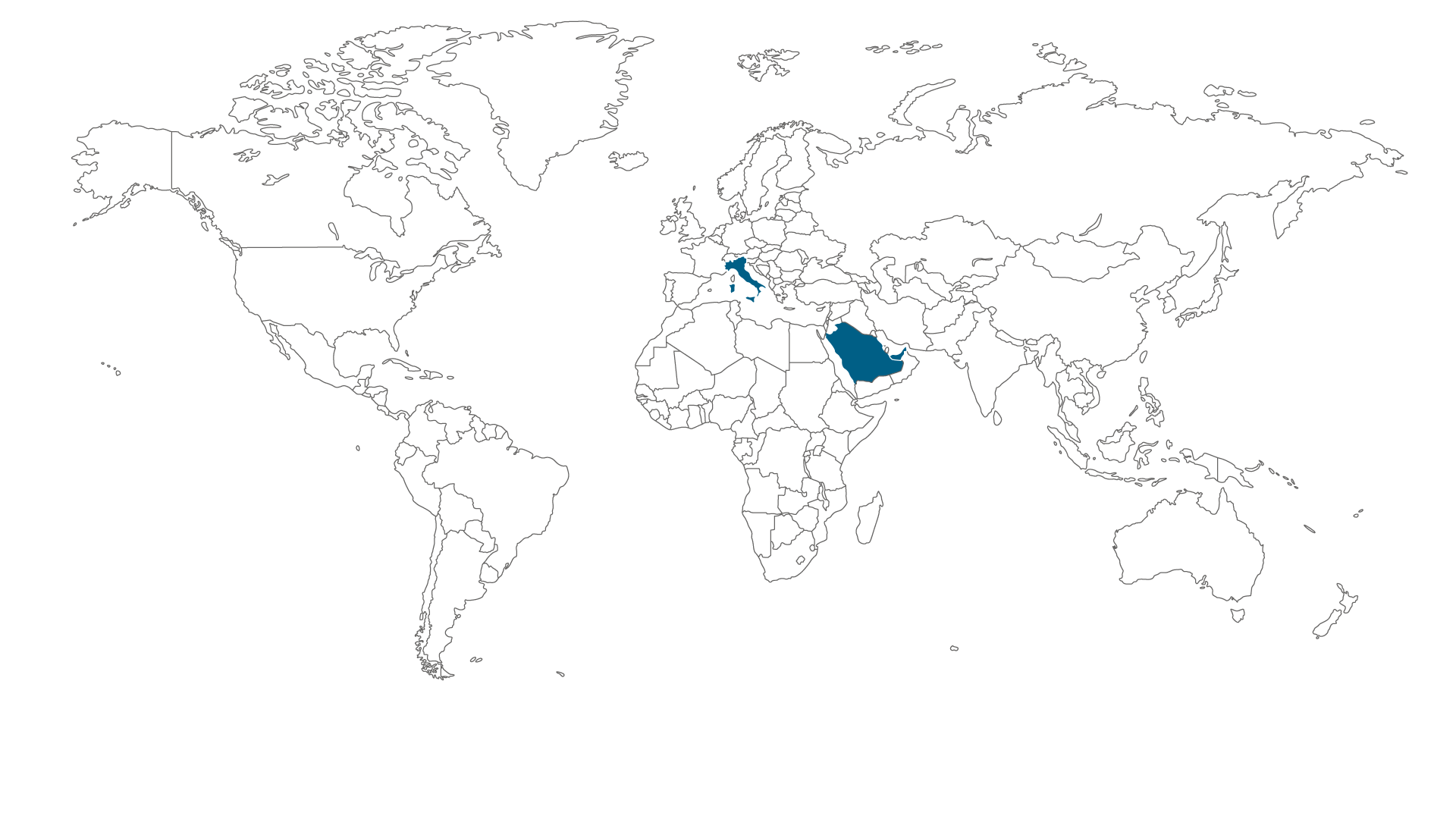

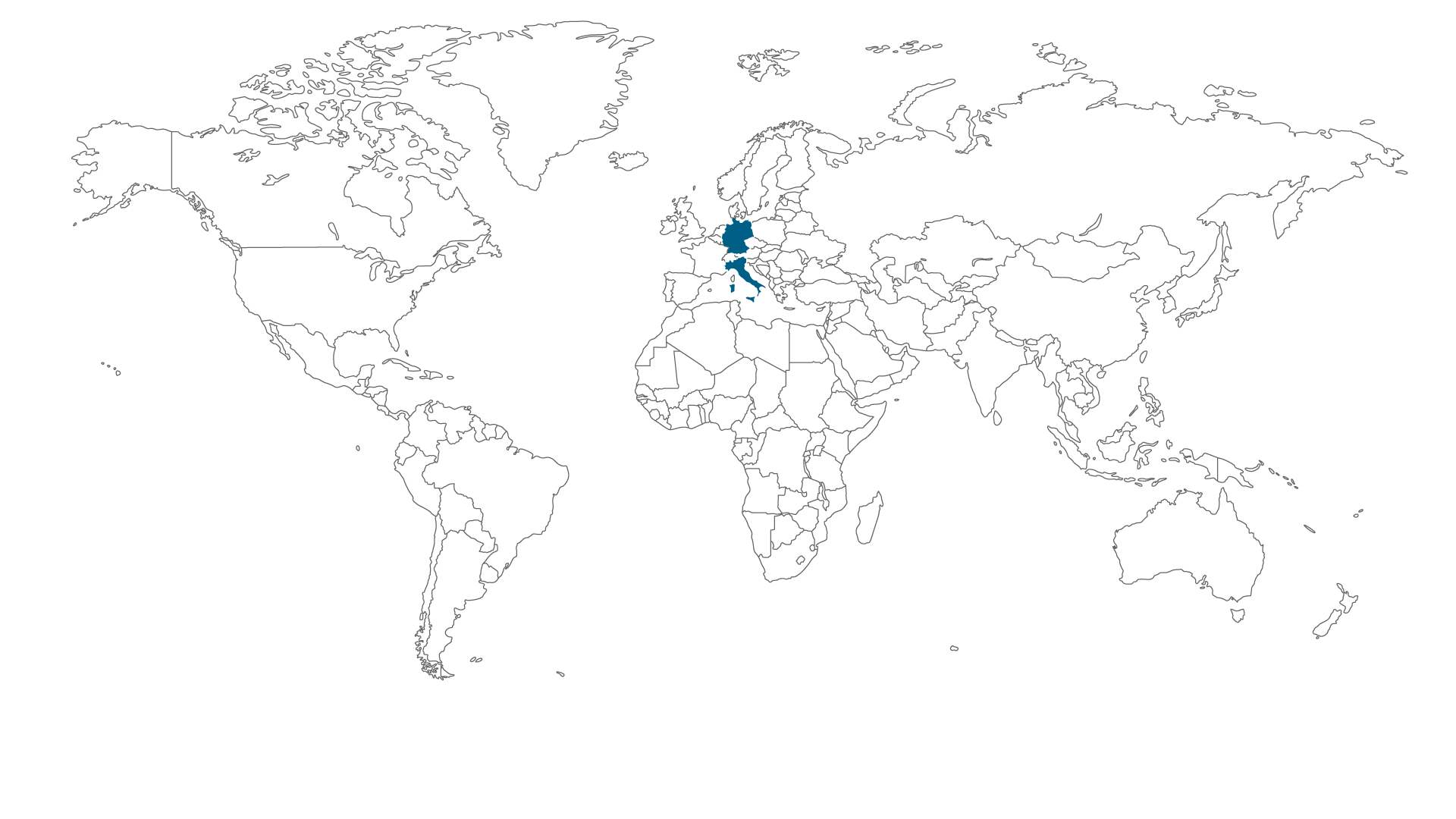

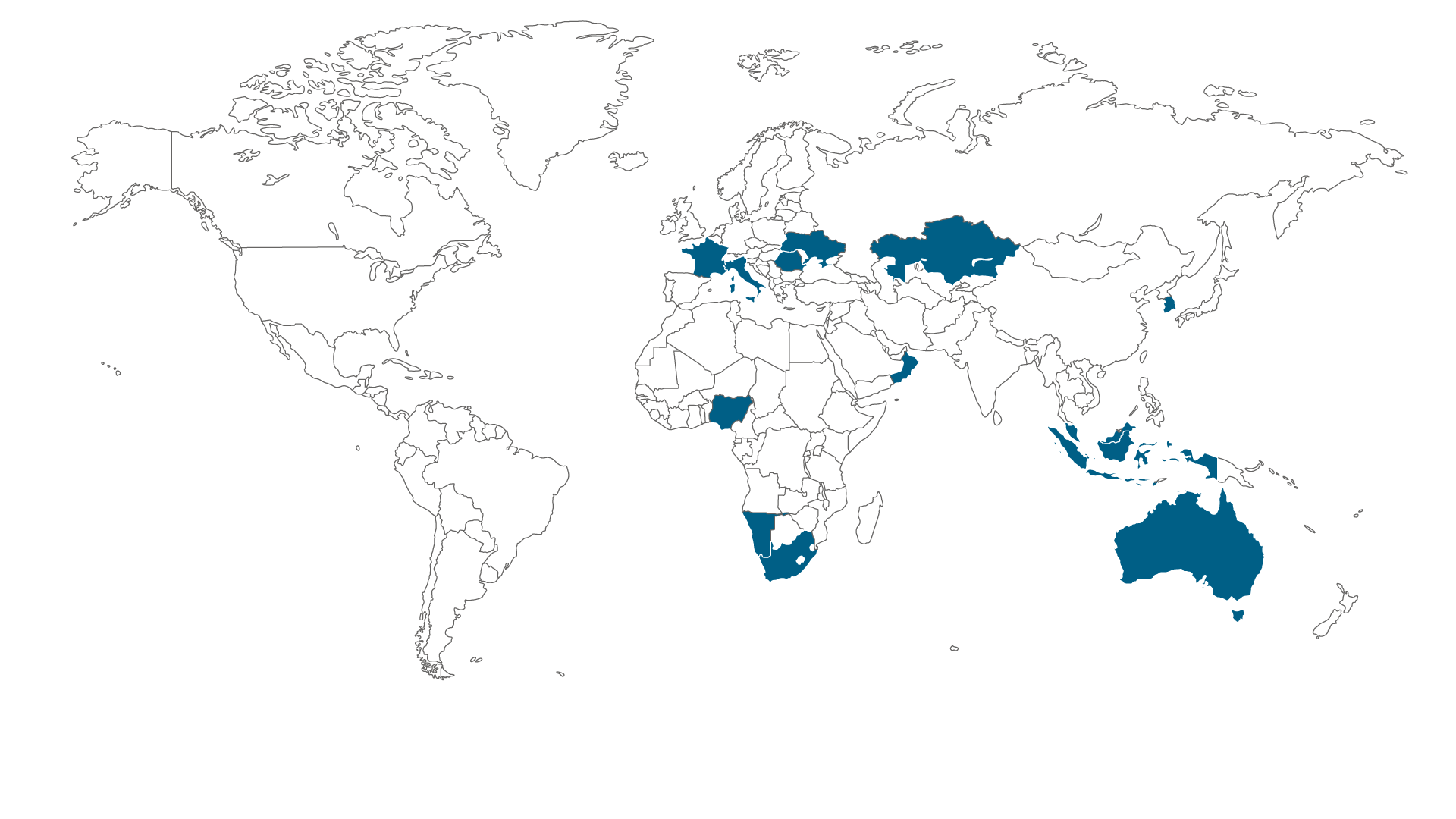

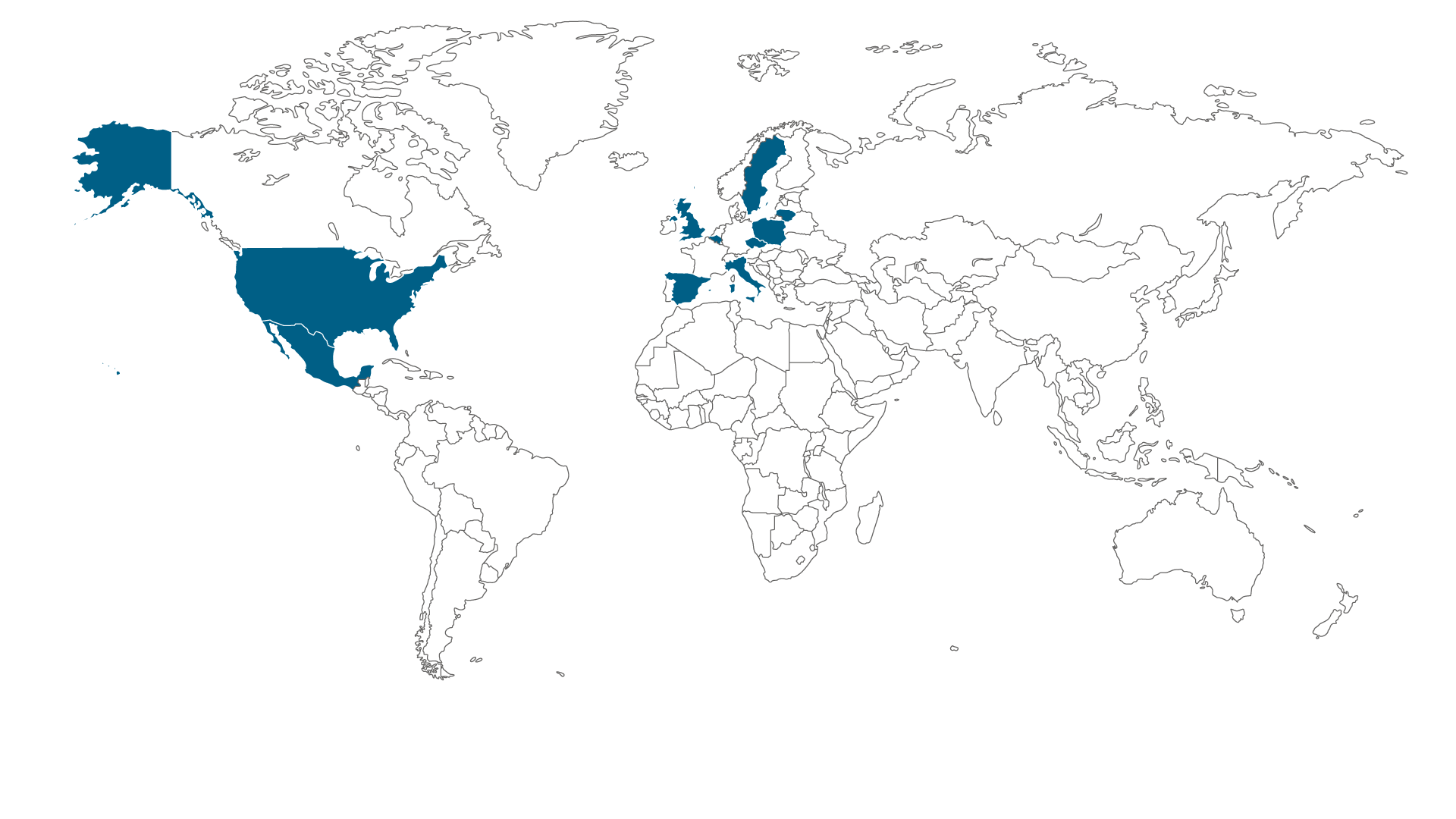

OLEOBI has a team of skilled operators able to intervene promptly on every type of hydraulic system. Upon customer’s request we provide worldwide assistance during machine assembly, commissioning, periodic maintenance.

Oleobi provides these services:

- Internal service (revision of hydraulic power units, hydraulic pumps and motors, test with certified test benches)

- Upgrade / Revamping of systems designed both by Oleobi and third-parties

- External call service 24/7

- Fluid treatment (removal of water from hydraulic oil, filtration, high pressure lines flushing)

- Scheduled customer maintenance

- Predictive maintenance using remote monitoring system

- Full Service Maintenance.

PREDICTIVE MAINTENANCE

Remote system CONDITION MONITORING to prevent, in due time, system ageing and/or damage to components

- VIBRATION ANALYSIS

- LUBRICANT TRIBOLOGICAL ANALYSIS

- INFRARED THERMOGRAPHY

OLEOBI is able to carry out on site computerized tests and measurements for the diagnosis and monitoring of hydraulic systems.

We perform functional tests on our test benches, simulating the operating conditions in which the system will work and monitoring the main parameters such as pressures, flow rates, temperatures, oil contamination, noise.

The graphs obtained not only allow the adoption of technical solutions aimed at perfecting the operation of the systems, but is also a valid technical documentation to complete the service.

For more info contact us at: service@oleobi.it

Skilled and experienced personnel

Oleobi constantly invests in personnel training and updating; our maintenance team consists of:

- Hydraulic technicians

- Electrical technicians

- Software technicians

who have obtained the following licences:

- BOSIET

- H2S

- Work at height