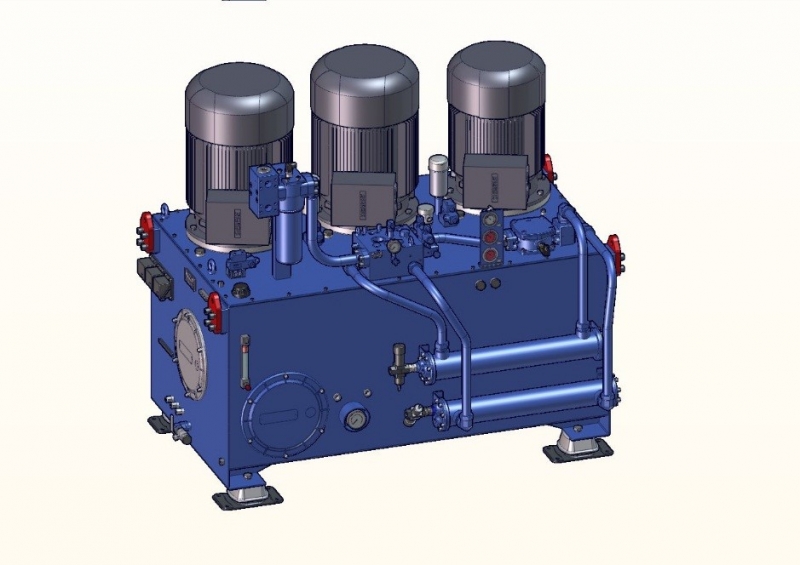

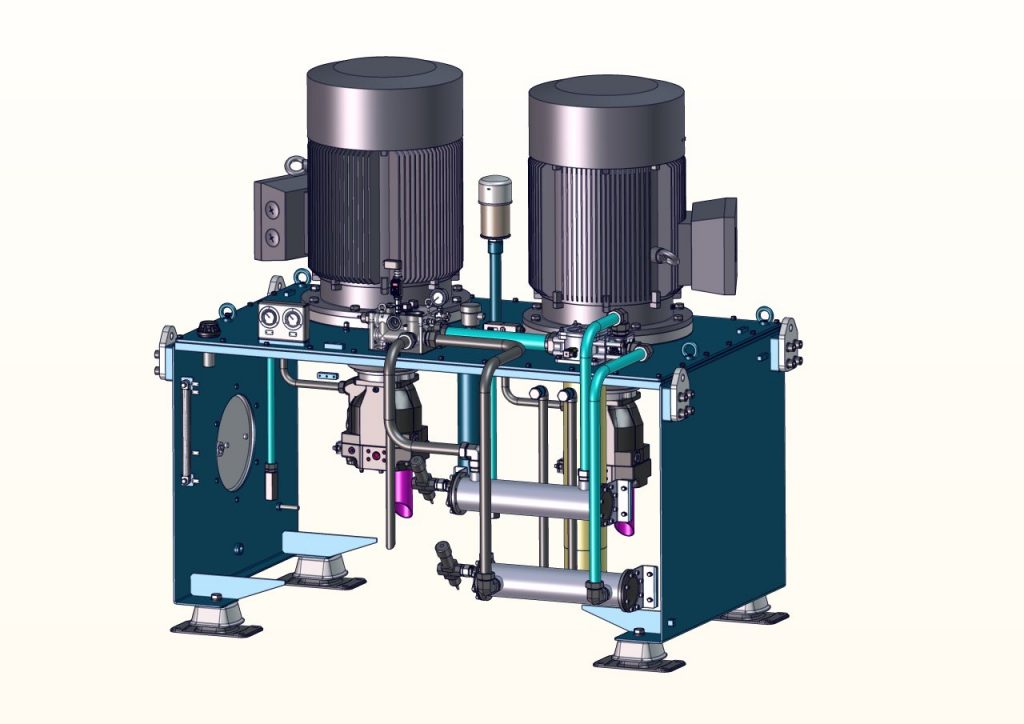

• HPU for the marine crane movement and rotation control.

• Power plant with electrical or endothermic engines.

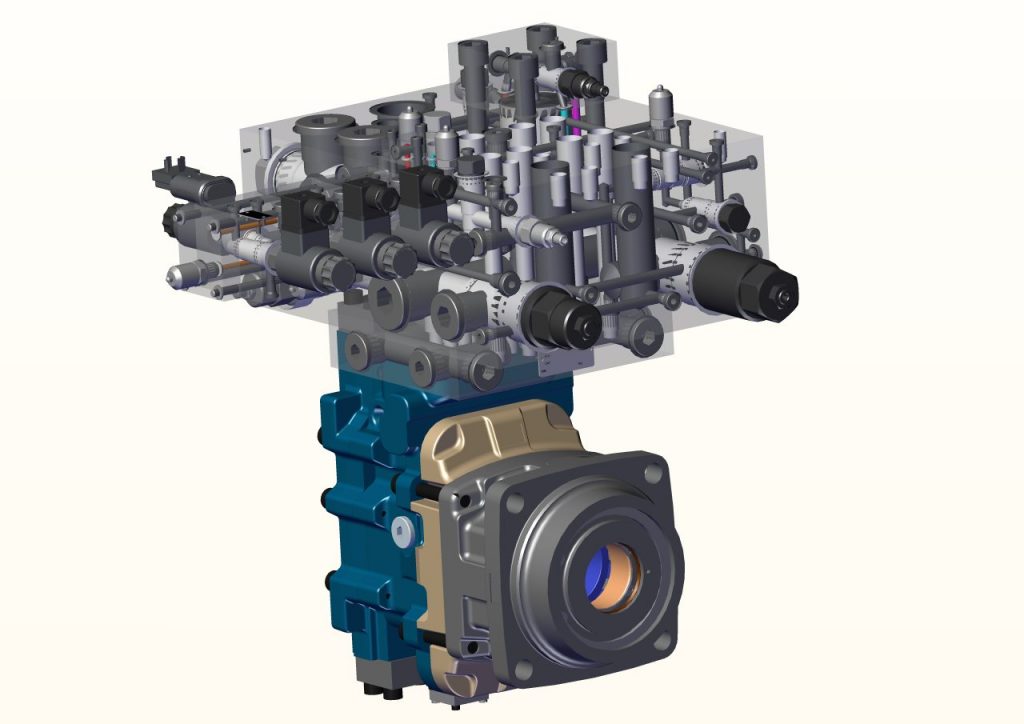

• Rotation control systems.

• Cylinder movement control systems.

Specific painting cycles for marine environments.

We can provide our clients with installations and systems approved by notified bodies, like DNV, ABS, Bureau Veritas, RINA, Lloyd Register, RMRS.

We can provide our clients with proportional control valves for really high capacities.

We can also supply our clients with ATEX certified equipment.

Expertise:

Power: up to 450 kW [600 hp]

Flow rate: up to 2.000 l/min [530 gpm]

Pressure: up to 420 bar [6000 psi]

Temperature: -40 °C +60 °C [-40 °F +140 °F]

Certifications: according to: DNV GL, ABS, BV, RINA, LR, CCS, KR, RMRS, ATEX, SIL requirements

Process Control: WPS, PQR, NDT, mechanical stress and wearing tests

Engineering international standards: IEC61508, IEC61511, ASME, EU Directives rules and specifications

Painting: C5M cycle, based on customer specifications

Surface treatments: phosphating, electrolytic protections, nitrocarburizing, stainlees steel surface finishing

Materials: AISI 316L, 6MO, duplex, tungum

- Aisi 316 valves

- Aisi 316 accumulators

- Proportional valves IECEx, ATEX, EAC

- Ermeto® DIN fittings

- Proportional Load Sensing Valves up to 2000 l/min

- Counterbalance Valves

- Manifold flanged directly onto motors

- Manifold, HPU (Hydraulic Power Unit) and Integrated System full engineering

- Fluid dynamics simulation

- Structural calculation

- Deep analysis and check of every single system parameter with specific and official report release

- Final operational test of the whole system

- World Wide commissioning with high level expertise technicians

- Rigid and flexible piping and on-site full assistance

- 40 years-experience in the hydraulic field and a very passionate team of engineers and technicians who work every day close to our customes